Rubber shredder

【Motor Power】:2*11-2*90kw

【Production capacity】:2T/h-8T/h

【Discharge size】:The coarse crushing effect is determined by the number of tool claws

【Supporting equipment】:Shredder host, power distribution cabinet, reducer * 2, motor * 2, magnetic separator.

【Applicable materials】:Suitable for shredding various rubber products such as engine oil filter rubber, waste tires, dust covers, etc.

【Rubber shredder Price】:(Please refer to the parameter price list below for details)

Telephone:13592521219

01. Equipment

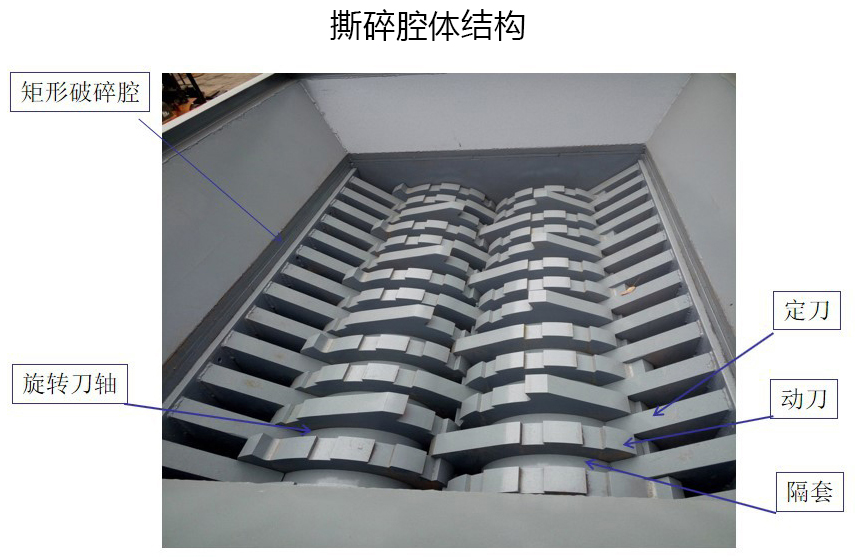

The rubber shredder is composed of a shredding machine body, two motors, a hard faced gear reducer, a hexagonal spindle, a fixed tool moving blade body, a rack workbench, and other structures. The rubber shredder equipment is easy to operate, has high production efficiency, strong tearing force, low rotational speed, and high noise. It can help users tear various types of rubber, car tires, etc. in bulk at once. The torn rubber blocks are then crushed and sorted to obtain recyclable rubber particles, powder, scrap iron wire, and other materials, with high economic value.

Haoxing Machinery, a manufacturer of shredders, has been committed to the upgrading and upgrading of rubber shredder equipment for many years, from tire shredders such as ring cutters, strip cutters, block cutters, and wire grinders to rubber shredders with higher work efficiency. To meet customer needs, Shuangxing Machinery continuously improves equipment quality and processes, providing excellent equipment guarantee for customer production.

02. Working principle

The rubber shredder is powered by a high torque motor. After the gearbox reducer slows down, the power is converted into strong torque and transmitted to the two shredder knife rollers. The two rotating knife rollers engage during rotation to complete the shredding of the rubber tire. The shredded rubber blocks are discharged from the machine body and undergo subsequent crushing by the rubber shredder, separation of iron wires by the magnetic separator, and grinding by the grinder to form rubber particles and powder, ultimately completing recycling.

03. Equipment advantages

1. The rubber shredding machine tool is made of alloy steel casting, with high hardness and long service life.

2. The steel plate of the equipment box can withstand high torque, is very sturdy, has a simple and durable structure, can be easily adjusted at a glance, and has low maintenance costs.

3. The rubber shredder equipment has advantages such as low speed, high torque, low noise, and no dust, fully meeting environmental production standards.

4. The thickness of the equipment's cutting tools and the number of claws can be customized, and can be replaced according to different shredding materials of customers to ensure the equipment's shredding efficiency.

04. Equipment price and model

Many rubber products in daily life can be recycled and reused. They are shredded into small enough particles using a rubber shredder, and then melted and reused in an extruder. Nowadays, people's lives cannot do without cars, which generates a large amount of tire rubber waste. Recycling tires is a big market, and rubber shredders are a good helper for efficient and practical rubber product recycling.

說點(diǎn)什么吧

- 全部評論(0)

還沒有評論,快來搶沙發(fā)吧!