Skip aluminum machine

【Motor Power】:5kw equipped with high-strength magnetic rollers

【productive power】:1-3 tons per hour

【Discharge size】:2cm-5cm metal ball

【Supporting equipment】:Metal shredder, scrap aluminum crusher, conveyor belt, skip aluminum machine, vibrating screen, etc

【Applicable materials】:Waste aluminum such as various raw aluminum, cast aluminum, aluminum alloy bridge cutting aluminum, aluminum profiles, etc

【The price of Skip aluminum machine】:Unified quotation for the entire set of equipment

Telephone:13592521219

01. Equipment

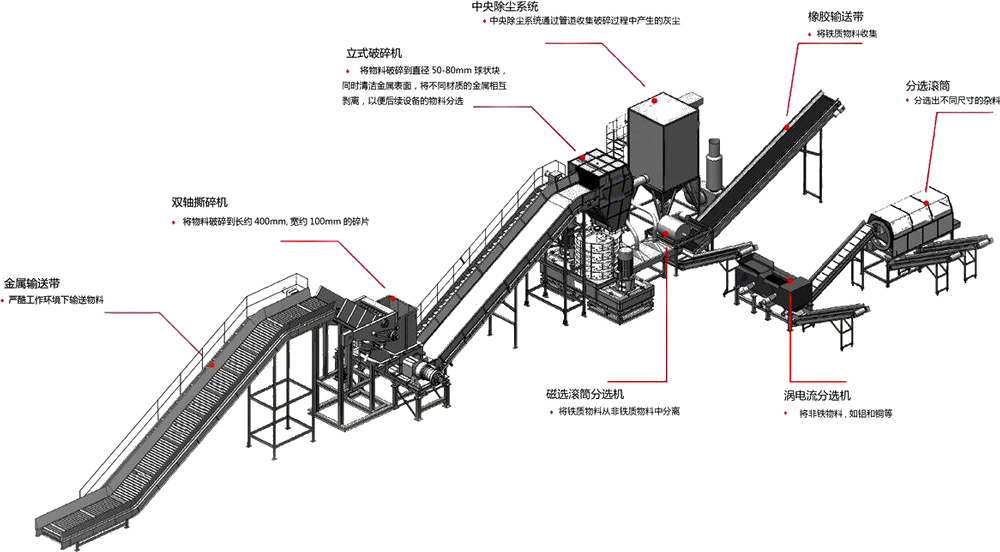

Jumping aluminum machine, also known as eddy current sorting machine, copper aluminum sorting machine, non-ferrous metal sorting machine, etc., specializes in sorting various waste aluminum, aluminum alloy, and raw aluminum materials. The aluminum skip machine has good sorting effects on various non-magnetic metals, effectively separating non-metallic materials from non-ferrous metals, automatically separating various non-ferrous metals, including waste aluminum and plastic, rubber, waste paper, and other materials.

02. Working principle

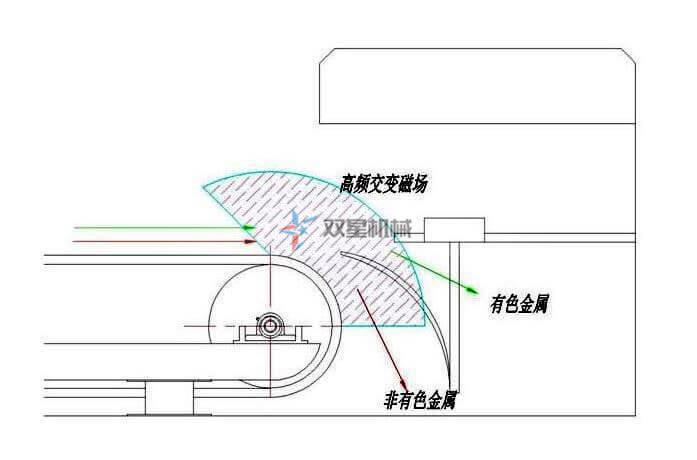

Jumping aluminum machine is a sorting method that utilizes the conductivity of various metal substances and the magnetic induction intensity generated by different metals. The sorting principle is to use a magnetic drum composed of high-strength magnets to rotate at high speed, generating alternating magnetic fields. When conductive metals pass through the magnetic field, eddy currents will be induced inside the metal. This eddy current itself will generate high-frequency alternating magnetic fields that are opposite to the magnetic field generated by the drum, while ferrous metals (copper, aluminum, zinc) will jump out along their conveying direction to separate from other non-metallic substances due to the opposite effect, achieving the purpose of sorting.

The aluminum skip machine has good sorting effects on various non-ferrous metals, effectively separating non-metallic materials and non-ferrous metals automatically, reducing labor, recycling non-ferrous metals, and effectively increasing output value. This product is mainly suitable for:

1. Crushing and sorting of plastic and rubber in broken bridge aluminum;

2. Crushing and sorting of metals and non-metals in waste aluminum;

3. Aluminum slag, aluminum ash, copper aluminum casting sand, sorting and collecting aluminum and copper during smelting;

4. In the dismantling and processing of household appliances, non-ferrous metals such as copper and aluminum are sorted out;

5. Separating metal aluminum from the crushed material of the can;

6. Copper, aluminum, and other metals are separated from materials such as discarded car wheels and engine casings through crushing.

7. The rubber and aluminum sheets in the car door and window rubber strips and waste tire fragments are separated.

03. Equipment advantages

Characteristics of aluminum jumping machine equipment

1. The equipment operation is simple. After the crushing equipment processes the particles in the material layer, the material passes through the conveyor belt to achieve metal and non-metal separation of the material;

2. The span of separable metal particles is large, usually between 3mm and 100mm.

3. Easy to install, customized according to customer needs, and can effectively connect with new and existing assembly lines.

4. Multiple models are available for selection (tray width can range from 300mm to 1500mm), and the production capacity and price of aluminum jumping machines vary depending on the model.

04. Equipment price and model

|

型號 |

適應(yīng)產(chǎn)量m3/h | 分選滾筒直徑mm | 磁鼓轉(zhuǎn)速r/min | 分選筒轉(zhuǎn)速r/min |

外形尺寸 長×寬×高 |

分選滾筒功率kw | 皮帶傳動功率kw | 重量kg |

| HBFX-40 | ≤4 | 320 | 50-2800 | 60-150 | 2885×1500×1695 | 4 | 1.1 | 1200 |

| HBFX-60 | ≤6 | 320 | 50-2800 | 60-150 | 2885×1700×1695 | 5.5 | 1.1 | 1350 |

| HBFX-80 | ≤8 | 320 | 50-2800 | 60-150 | 2950×1900×1695 | 5.5 | 1.5 | 1500 |

| HBFX-100 | ≤10 | 400 | 50-2800 | 60-150 | 2950×2100×1695 | 7.5 | 1.5 | 1900 |

| HBFX-120 | ≤12 | 400 | 50-2800 | 60-150 | 2950×2400×1695 | 7.5 | 1.5 |

2100 |

說點什么吧

- 全部評論(0)

還沒有評論,快來搶沙發(fā)吧!